Take a look around your home or office; chances are you’re surrounded by packaging waste from products you’ve purchased. All that cardboard, plastic, and foam adds up to create a massive environmental burden. But companies and consumers alike can take steps to significantly cut down on packaging waste.

Rethink Product Protection

A major driver of packaging waste stems from a mindset of overprotecting products during shipping and handling. While ensuring items arrive undamaged is important, there’s often room to scale back excessive protective packaging without compromising safety.

Forward-thinking companies analyze their entire supply chain to locate areas where packaging can get streamlined or simplified. Techniques like improved palletizing and custom-fitted package inserts allow using less void-fill material. Simple changes in boxing dimensions based on real product size also save big on wasted corrugated material.

Meanwhile, major Styrofoam manufacturers like those at Epsilyte now promote alternatives made from recycled materials that are just as protective yet far more environmentally friendly than traditional foam cushioning. With a little creativity, effective product protection and sustainability can go hand-in-hand.

Embrace Sustainable Packaging

Of course, another huge component of packaging waste stems from companies using excessive or non-renewable materials in the first place. But the rise of plant-based, recyclable, and biodegradable packaging gives brands plenty of eco-friendly options to implement instead.

Molded fiber packaging made from sources like bamboo, mushrooms or sugarcane bagasse provides exceptional protection comparable to Styrofoam yet biodegrades easily after use. Companies can also incorporate recycled content into polyethylene plastic packaging and corrugated boxes.

Optimize Package Design

Packaging design itself plays a huge role in minimizing superfluous waste. Applying smart structural design principles ensures packages effectively protect contents while using no more material than absolutely required.

For example, sophisticated computer modeling allows designers to analyze exactly how distribution forces and impacts will get transferred through a package during transit. With these insights, reinforcements and absorptive materials get strategically placed only where needed rather than applied superfluously throughout.

Implement Closed-Loop Recycling

For that unavoidable packaging waste that does get generated, advanced recycling practices those materials to be captured and reused repeatedly rather than sending them to landfills or incinerators. It is all part of the circular economy mindset, revolutionizing how companies approach material flows.

Leading brands implement closed-loop recycling streams that collect used packaging from consumers and retailers, then process those materials for direct reincorporation into new packaging production cycles. Innovations like chemical recycling that breaks down plastic waste into component molecules even allow recycling traditionally non-recyclable materials.

Innovative Waste Solutions

Materials science continues uncovering innovative packaging waste solutions, too. Researchers work on exciting developments like ultra-thin coatings to repel moisture and contaminants that allow using less preservative packaging. Edible, digestible packaging films could eventually replace non-renewable options altogether.

Designers also reinvent packaging for reusable life cycles, like shipping containers constructed as standardized modules that simply join and detach rather than generating disposable waste. Adopting a reuse-over-disposal mindset sparks remarkably inventive packaging innovations.

Conclusion

While packaging will likely always generate some amount of waste, companies clearly have a plethora of paths to vastly reduce their environmental impact moving forward. Optimizing designs, embracing sustainable materials, recycling comprehensively, and rethinking excessive package protection means the packaging footprint can shrink dramatically.

Granted, reinventing packaging practices is not necessarily cheap or easy; it takes concerted investment and commitment from brands. But for companies looking to enhance their eco-credentials, deliver on consumer sustainability demands, and realize long-term cost efficiencies, cutting packaging waste provides a worthwhile win-win opportunity. The future of efficient, responsible packaging is already here; we just need to fully adopt and implement it.

Why Hiring Professional Carpet Cleaners Is Essential for Pennsylvania Homes and Businesses

Why Hiring Professional Carpet Cleaners Is Essential for Pennsylvania Homes and Businesses  How to Care for Leather Sofas: Everything You Need to Know

How to Care for Leather Sofas: Everything You Need to Know  Tips to Choose the Best Housekeeping Services in UAE

Tips to Choose the Best Housekeeping Services in UAE  Best Practices for Cleaning Medical Facilities

Best Practices for Cleaning Medical Facilities  Tips for refreshing the house in the spring.?

Tips for refreshing the house in the spring.?  Gypsum in Cement and Plaster: Why It’s Essential

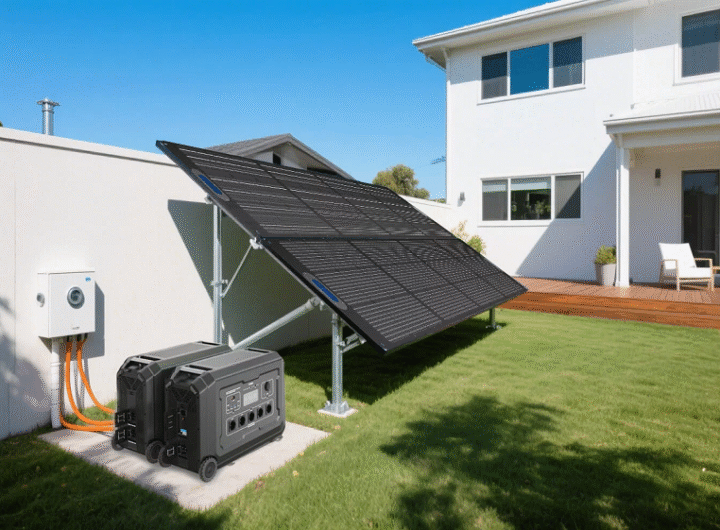

Gypsum in Cement and Plaster: Why It’s Essential  Home Backup to Outdoor Power: Understanding Solar Generator Systems

Home Backup to Outdoor Power: Understanding Solar Generator Systems  Can I Replace the Fridge Seal Myself?

Can I Replace the Fridge Seal Myself?  How to Celebrate Christmas in a Log Cabin

How to Celebrate Christmas in a Log Cabin